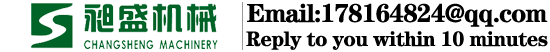

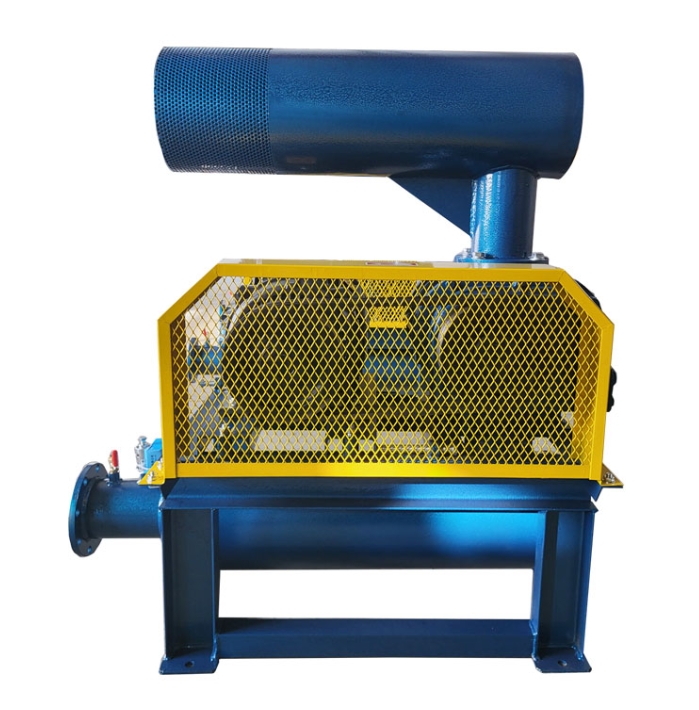

The two-stage high-pressure Roots blower achieves high-pressure output through a two-stage series structure, which has the characteristics of high pressure difference, high efficiency, strong stability, and compact structure. It is suitable for industrial scenarios that require high pressure and stable gas sources. The following is a detailed analysis of its key characteristics and applications:

1、 Core Features

Double stage series boosting

Composed of two standard Roots blowers connected in series, the gas is pressurized in the first stage and cooled to below 40 ℃ through an intercooler before entering the second stage blower for secondary boosting. The final output pressure can reach 177kPa (some models can increase it to 196kPa), significantly higher than single-stage blowers (below 98.8kPa).

High efficiency and stability

Dual stage compression design: improves compression ratio, reduces energy consumption, and minimizes exhaust temperature fluctuations.

Three blade rotor structure: optimizes airflow pulsation, reduces vibration and noise, and runs more smoothly.

Synchronous gear transmission: Ensure that the two-stage rotors rotate synchronously in opposite directions to avoid mechanical interference.

Compact structure and reliability

Modular design: Two stage fans share the same motor (belt drive or dual axis straight connection), reducing the footprint.

High precision gap control: The gap between the rotor and the casing is strictly controlled to avoid friction or locking risks, but regular maintenance is required.

High temperature resistant design: supports high temperature working conditions (such as drying exhaust gas transportation), equipped with high temperature resistant bearings and cooling system.

2、 Typical application scenarios

High pressure gas delivery

Long distance/high resistance pipelines: Provide stable pressure output in scenarios where the pipeline length exceeds 50 meters or the system resistance is high (such as dense bends, multi-stage filtration).

Pneumatic ash conveying: In thermal power plants, ash is conveyed through high-pressure airflow or vacuum pumps are installed to extract gas from pipelines.

Industrial process pressurization

Combustion assistance in cement production: high-pressure gas is introduced from the bottom of the kiln to promote the vertical descent of materials and the firing of clinker.

Chemical raw material transportation: processing reaction gases, wastewater treatment, ventilation and exhaust, etc., to meet high pressure requirements.

Special environment adaptation

Explosion proof/anti-corrosion requirements: Explosion proof type (ExdIIBT4 certification) should be selected in flammable and explosive workshops (such as dusty environments), and stainless steel material or anti-corrosion treatment should be used when transporting corrosive gases.

Clean and oil-free requirements: No need for lubricating oil to come into contact with gas, suitable for industries such as food and medicine that require strict cleanliness.

3、 Selection and maintenance points

Selection criteria

Pressure and flow matching: Determine the pressure range (above 98.8kPa) and volume flow rate under standard conditions according to process requirements.

Adaptation of medium characteristics: For dusty, high-temperature, or corrosive gases, choose models made of wear-resistant, heat-resistant, or corrosion-resistant materials.

Redundant design: It is recommended to adopt a one in use and one backup configuration for key processes to ensure continuous operation.

Maintain key

Regular maintenance: replace lubricating oil, clean air filters, check belt tightness and gear engagement.

Operation monitoring: Pay attention to bearing temperature (≤ 75 ℃), vibration value (≤ 4.5mm/s), and muffler noise. If any abnormalities are found, stop the machine immediately.

Shutdown standard: When shutting down, first open the bypass pipe to release air, and then cut off the power after the air pressure drops to zero to avoid equipment damage.