Roots blower and vortex blower have differences in multiple aspects, and the following comparative analysis is conducted from multiple dimensions:

1、 Working principle and structure

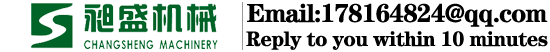

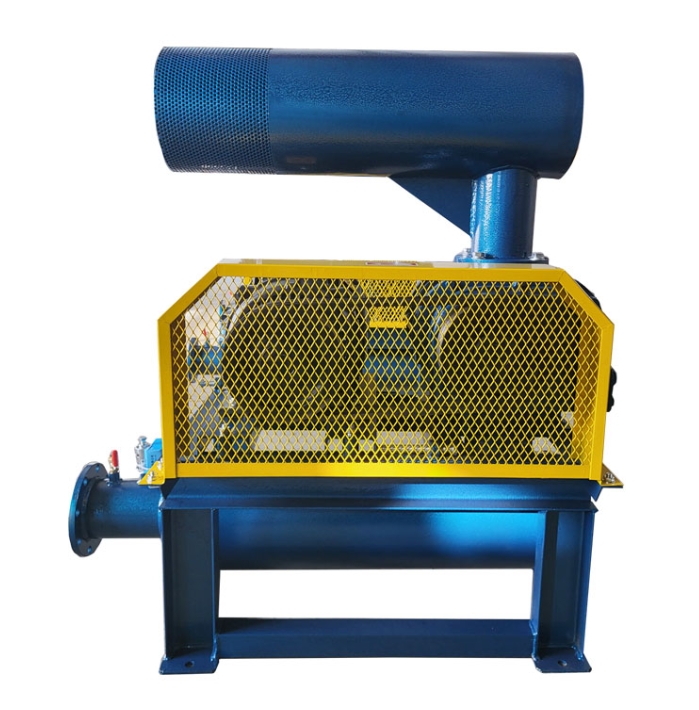

Roots blower:

Type: positive displacement fan.

Structure: Two leaf shaped rotors (usually three bladed) are used to move relative to each other inside the cylinder, and gas is forcibly delivered through small gaps between the rotors. The rotors are not in contact with each other and are maintained in mesh by synchronous gears.

Principle: Gas is sucked in, compressed, and discharged during the rotation of the rotor, and the flow rate is proportional to the speed. The pressure selection range is wide, and it has the characteristic of forced gas transmission.

Vortex fan:

Type: Turbine fan (a type of high-pressure fan).

Structure: The impeller is composed of dozens of blades, similar to a gas turbine impeller. When the impeller rotates, the air is subjected to centrifugal force and moves towards the edge, entering the annular cavity of the pump body and circulating again, forming a spiral airflow.

Principle: Air is uniformly accelerated and leaves the pump body with energy, at a pressure 12-17 times that of a centrifugal fan with the same diameter and speed.

2、 Performance characteristics

Roots blower:

Pressure and flow rate: The output pressure is relatively high (9.8-196kPa), the flow rate is stable, and it is less affected by pressure changes, making it suitable for medium to high pressure and low flow scenarios.

Efficiency and energy consumption: Low pressure conditions have high efficiency (>70), but efficiency decreases at high pressure, resulting in relatively high energy consumption.

Noise and maintenance: The operating noise is relatively high (>85dB), requiring regular lubrication and replacement of gear grease, resulting in high maintenance costs.

Material and temperature resistance: The main material is cast iron, which has good temperature resistance, but attention should be paid to the lubricating oil performance at high temperatures.

Vortex fan:

Pressure and flow rate: Low output pressure (<8kPa), relatively large flow rate, suitable for low-pressure and high flow scenarios.

Efficiency and energy consumption: The work efficiency is about 85%, and the energy consumption problem is prominent under high pressure and large air volume.

Noise and maintenance: Low noise level (<80dB), maintenance free use, with only bearings as wear and tear parts, and basically no maintenance required during the warranty period.

Material and Temperature Resistance: The main material is aluminum alloy, which is lightweight but has poor temperature resistance and is prone to oxidation at high temperatures.

3、 Application scenarios

Roots blower:

Industrial fields: pneumatic conveying (such as grain and cement), vacuum adsorption (such as printing and packaging), aquaculture oxygenation, and wastewater treatment aeration.

Special working conditions: Suitable for scenarios that require medium to high pressure, constant flow, and small volume, such as high-pressure working conditions and special gas delivery.

Vortex fan:

In the fields of industry and agriculture: paper cutters, combustion oxygen reducers, cigarette filter forming machines, electroplating tank liquid agitation, atomization dryers, fish farming and oxygenation, water treatment aeration.

General scenario: Suitable for low-pressure, high flow, high noise and energy consumption requirements scenarios, such as small-scale sewage treatment systems, infrastructure, and environmental protection industries.

4、 Selection suggestions

Preferred Roots blower:

High pressure and constant current requirements: such as large-scale sewage treatment systems, pneumatic conveying, vacuum adsorption, etc.

High corrosion resistance requirements: Roots blowers have stronger corrosion resistance and are suitable for transporting special gases.

Priority should be given to vortex fans:

Low pressure, high flow demand: such as small sewage treatment systems, infrastructure, and environmental protection industries.

Noise and energy sensitivity: Vortex fans have low noise and relatively low energy consumption, making them suitable for scenarios with high requirements for noise and energy consumption.