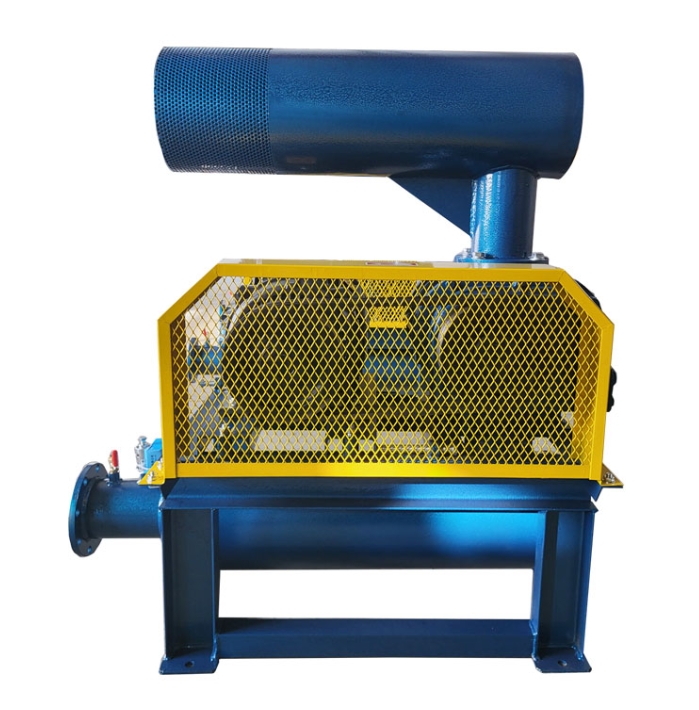

The installation and commissioning process of Roots blower needs to strictly follow the specifications to ensure the normal operation and service life of the blower. Here are some precautions during the installation and debugging process:

Installation precautions

-* * Basic installation**

-The fan should be installed on a horizontal and sturdy foundation, and the bearing capacity of the foundation should meet the weight and vibration requirements of the fan during operation. The basic surface should be flat, and the horizontal deviation should not exceed the specified value.

-Reserve anchor bolt holes on the foundation, and the anchor bolts should be installed vertically. Their burial depth and tightening torque should comply with the requirements of the fan installation manual.

-Pipeline connection**

-When connecting the inlet and outlet pipes of the fan, attention should be paid to avoiding the transmission of stress from the pipes to the fan. The weight of the pipeline should not be supported by the fan, and can be fixed using brackets or hangers.

-The connection between the pipeline and the fan should use flexible connection methods, such as rubber soft joints, to reduce the propagation of vibration and noise. The connecting bolts should be tightened evenly to prevent leakage.

-Necessary valves and filters should be installed on the inlet and outlet pipelines to facilitate the operation and maintenance of the fan and prevent impurities from entering the interior of the fan.

-Fan installation**

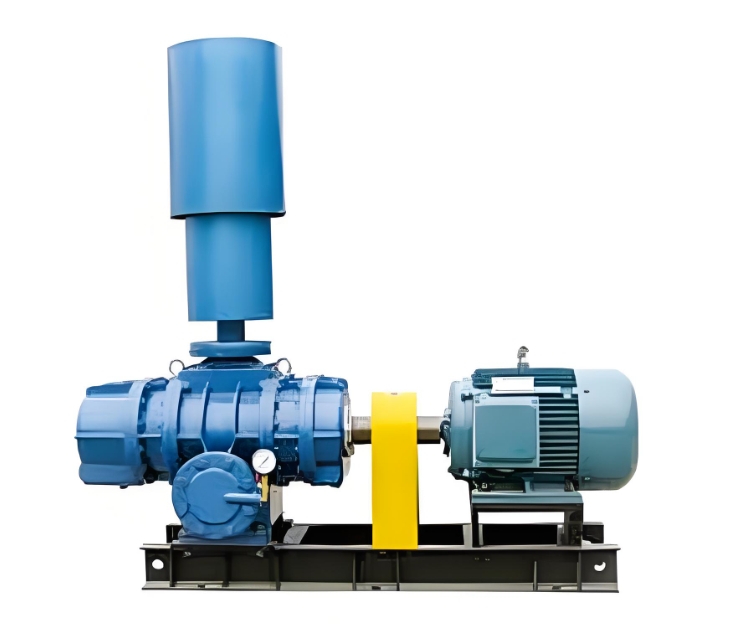

-When installing the fan, it should be ensured that the installation position of the fan is correct, the fan shaft and the motor shaft should be kept concentric, and the coaxiality deviation should meet the specified requirements. The fan and motor can be connected by coupling or belt transmission, and the connection should be firm and reliable. The tension of the transmission belt should be appropriate.

-During the installation process, attention should be paid to protecting the impeller and casing of the fan to avoid collision and damage. The interior of the fan should be cleaned thoroughly and there should be no debris residue.

-Check the lubrication system and cooling system of the fan (if any) to ensure that the oil level and quality of the lubricating oil meet the requirements, the cooling water pipeline is connected correctly, and there is no leakage.

Debugging precautions

-* * Check before startup**

-Recheck if the connection between the fan and the pipeline is secure, and if the valve is in the correct open position.

-Check if the wiring of the motor is correct and if the insulation resistance meets the requirements. Manually rotate the fan impeller and check for flexible rotation, as well as any signs of jamming or friction.

-Confirm that the lubrication system and cooling system are working properly, whether the lubrication oil pump can supply oil normally, and whether the cooling water temperature and pressure meet the regulations.

-* * No load trial operation**

-Connect the power supply and conduct a no-load test run. When starting, the starting current and time of the fan should be observed. If any abnormalities are found, the machine should be stopped immediately for inspection.

-During the no-load operation, check the sound, vibration, and bearing temperature of the fan. The vibration value of the fan should be within the specified range, and the bearing temperature should not exceed the allowable value. At the same time, observe whether the pressure and oil temperature of the lubricating oil are normal. If there are any abnormalities, they should be adjusted and dealt with in a timely manner.

-Check if the rotation direction of the fan is correct. If the direction is incorrect, stop the machine and adjust the motor wiring before restarting. The no-load trial run time is generally 2-4 hours, and the load trial run can be carried out after there are no abnormal phenomena.

-* * Load trial operation**

-After the no-load test run is normal, gradually increase the load of the fan until it reaches the rated working condition. During the loading process, it is necessary to closely observe the various operating parameters of the fan, such as wind volume, wind pressure, current, voltage, temperature, etc., to ensure that they are within the specified range.

-Check the vibration and noise of the fan during load operation. If there is abnormal vibration or increased noise, analyze the cause and take appropriate measures. It may be caused by resonance of the pipeline system, imbalance of the impeller, or malfunction of other components.

-The load test run time is generally not less than 8 hours. During this period, the operation status of the fan should be checked to confirm that there are no problems before it can be considered as qualified for debugging.

During the installation and debugging process, it is necessary to strictly follow the installation instructions and relevant specifications of the Roots blower to ensure installation quality and debugging effectiveness. If encountering complex problems or uncertain situations, it is necessary to consult the fan manufacturer or professional technicians in a timely manner.