Roots blower and centrifugal blower are two different types of fans, with significant differences in their working principles, structural characteristics, performance parameters, and application scenarios. The following is a detailed comparative analysis:

---

**1、 Comparison Table of Core Differences**

|* * Comparison item * * | * Roots blower * * | * * Centrifugal blower * *|

|------------------|----------------------------------|----------------------------------|

|* * Working principle * * | Volumetric (forced delivery of gas through impeller engagement) | Kinetic (acceleration of gas through impeller centrifugal force)|

|* * Flow pressure characteristics * * | Constant flow rate, pressure changes with system resistance | Significant flow rate changes with pressure (with working curve)|

|Efficiency range * * | 60-75 | 70-85 (wider zone)|

|* * Pressure * * | Up to 98kPa (0.98bar) | Typically ≤ 30kPa (0.3bar)|

|* * Flow regulation * * | Variable frequency or bypass regulation required | Flexible adjustment through inlet guide vanes/variable frequency|

|* * Structural Features * * | Double bladed wheel+synchronous gear, clearance | Single bladed wheel+volute, contactless sealing|

---

**2、 Differences in working principles**

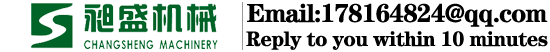

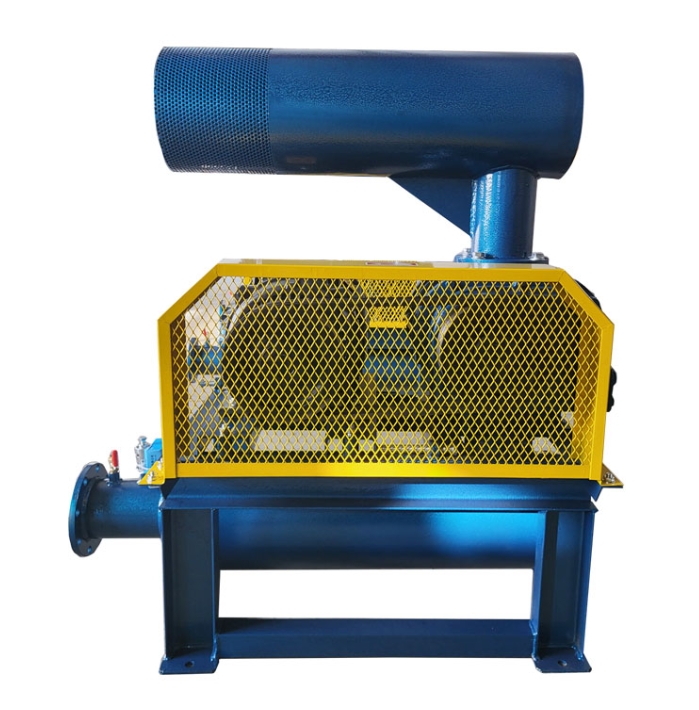

**1. Roots blower (positive displacement)**

-* * Working process * *:

Two three or two bladed rotors rotate in opposite directions inside the casing, achieving gas delivery by periodically changing the chamber volume.

```mermaid

graph LR

A [intake] -->B [rotor meshing forms a closed cavity]

B -->C [Decreased cavity volume]

C -->D [Gas forced out]

```

-* * Features * *:

-The flow rate is proportional to the rotational speed and is almost unaffected by pressure

-The outlet pressure is determined by the system back pressure

**2. Centrifugal fan (kinetic energy type)**

-* * Working process * *:

The rotation of the impeller gives kinetic energy to the gas, and the volute converts the kinetic energy into static pressure energy.

```mermaid

graph LR

E [Axial intake] -->F [Centrifugal acceleration of impeller]

F -->G [snail shell expansion]

G -->H [High pressure discharge]

```

-* * Features * *:

-Pressure flow follows a parabolic relationship (effective point)

-There is a risk of surge (to avoid unstable operating conditions)

---

**3、 Performance Curve Comparison**

|* * Features * * | * Roots blower * * | * * Centrifugal blower * *|

|----------------|------------------------------|------------------------------|

|* * Flow curve * * | Approximate vertical line (constant flow) | Parabola (flow rate varies with pressure)|

|Efficiency curve * * | relatively flat (60-75) | spike shaped (narrow region)|

|Overload capacity * * | Can operate under short-term overpressure | Overpressure can cause surge|

---

**4、 Select application scenarios**

**Priority selection of Roots blower**

1. Constant flow conveying is required (such as pneumatic conveying, backwashing)

2. High pressure and low flow conditions (>30kPa and<50m3/min)

3. The medium contains * * dust or particulate matter * * (with better wear resistance design)

4. In situations where a simple and easy to maintain structure is required

**Priority selection of centrifugal fans**

1. * * High flow medium low pressure * * demand (such as ventilation, boiler induced draft)

2. Continuous operation system that requires * * energy-saving * *

3. Environment sensitive to noise (centrifugal fans are quieter)

4. In situations where the operating parameters * * fluctuate greatly * *

---

**5、 Maintenance and Cost Comparison**

|* * Project * * | * Roots blower * * | * * Centrifugal blower * *|

|---------------|---------------------------|---------------------------|

|* * Maintenance frequency * * | Change gear oil every 2000 hours | Check bearings every 5000 hours|

|* * Vulnerable parts * * | Synchronous gears, shaft seals | Bearings, impeller dynamic balancing|

|* * Life cycle * * | 5-8 years (impeller repairable) | 8-12 years (overall replacement)|

|* * Purchase cost * * | Low (20-30% cheaper for the same power) | High|

|* * Operating cost * * | High (low efficiency) | Low (energy-saving zone)|

---

**6、 Common Misunderstandings Clarification**

1. * * Misconception * *: "Roots blower is a type of centrifugal blower"

-Fact: Both belong to volumetric and kinetic fans, with different principles

2. * * Misconception * *: "Roots blower has lower efficiency than centrifugal blower"

-Fact: Under low flow and high pressure conditions of less than 30m3/min, Roots blower efficiency may be higher

3. * * Misconception * *: "Centrifugal fans cannot be used for pneumatic conveying"

-* * Fact * *: Specially designed centrifugal fans (such as multi-stage boosting) can also be used for conveying

---

**7、 Technology integration**

1. Magnetic levitation Roots blower:

-Combining magnetic levitation bearing technology to eliminate gear transmission

-Efficiency has been improved to over 80 (traditional Roots blower is about 65)

2. * * High speed centrifugal blower * *:

-Adopting a ternary flow impeller, the pressure can reach 50kPa

-Replace Roots blower in some fields (such as sewage treatment)

---

**Summary and Suggestions**

-* * Selection principle * *: Select the type of fan based on the * * system resistance curve * *

-* * Key judgment points * *:

-Need constant flow → Choose Roots

-Need to change flow rate → choose centrifuge

-* * Special working conditions * *:

-Dust containing gas → Roots (more mature wear-resistant design)

-High flow rate of clean air → centrifugation

For specific selection support, please provide:

① Required flow range ② System pressure requirements ③ Medium characteristics (temperature/humidity/dust content)