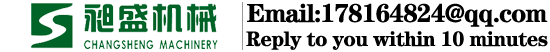

**Detailed explanation of the working principle of Roots blower**

Roots blower is a type of positive displacement fan that uses two interlocked rotors to rotate within a sealed chamber, achieving forced gas delivery. Its core feature is * * no internal compression, constant volume delivery * *, suitable for gas transmission scenarios with medium and low pressure and high flow rate.

---

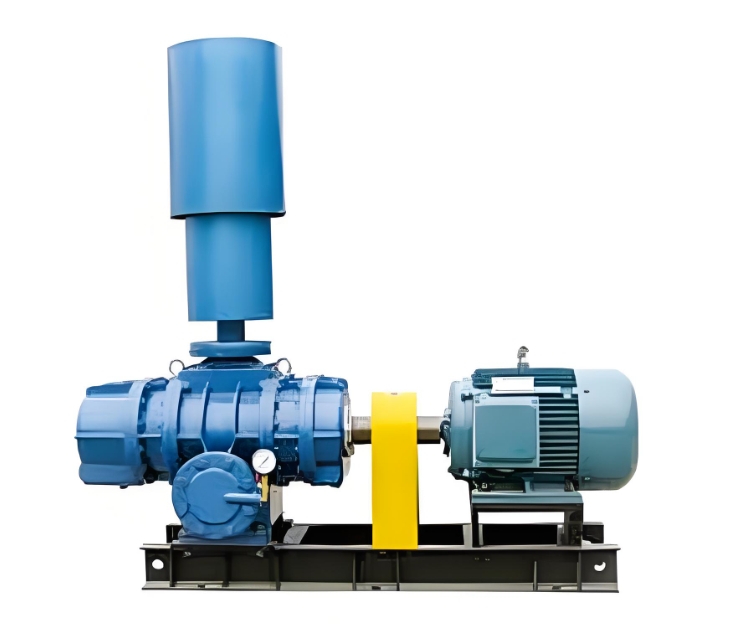

**1、 Core structure composition**

|* * Component * * | * * Function Description * *|

|----------------|-----------------------------------------------------------------------------|

|* * Chassis * * | Enclosed chamber, usually made of cast iron or stainless steel material, forming a gas delivery channel|

|* * Rotor * * | Two or three "∞" - shaped impellers, maintaining a small gap (0.1~0.4mm) with each other, rotate in opposite directions|

|* * Synchronous gear * * | Ensure precise synchronization of the two rotors to avoid contact wear|

|* * Inlet/outlet * * | Unidirectional gas flow, no valve design|

|Sealing System * * | Preventing Gas Leakage (Commonly Used Mechanical Seals or Maze Seals)|

---

**2、 Working principle (three-step analysis)**

**1. Inhalation stage**

-When the rotor rotates, the volume of the intake side chamber gradually increases, forming negative pressure.

-External gas is drawn into the chamber (without compression, only volume displacement).

**2. Closed conveying stage**

-The rotor continues to rotate, sealing the gas in the "air pocket" formed by the rotor and the casing.

-* * Key feature * *: The gas is not compressed inside the chamber and only moves with the rotor (different from screw compressors).

**3. Exhaust stage**

-The engagement of the rotor pushes the gas towards the outlet, reducing the volume of the chamber and forcing the gas to be discharged.

-The exhaust pressure is determined by the resistance of the backend pipeline network (the higher the pressure, the greater the load).

```mermaid

graph LR

A [intake] -->B (negative pressure formed by rotor rotation)

B -->C (gas enclosed transportation)

C -->D [Exhaust]

```

---

**3、 Core Features**

1. * * No internal compression**

-Pressure dependent system back pressure, * * theoretical compression ratio=1 * * (actual slight compression due to leakage).

-The exhaust temperature is relatively low (usually<100 ℃), suitable for transporting flammable and explosive gases.

2. * * Constant volume conveying**

-The flow rate is proportional to the rotational speed and is independent of pressure (to prevent overpressure operation).

3. * * Forced delivery**

-Even if the system resistance changes, stable flow can still be maintained (but the motor load will change).

---

**4、 The difference between centrifugal fan and screw fan**

|* * Comparison item * * | * Roots blower * * | * * Centrifugal blower * * | * * Screw blower * *|

|------------------|----------------------------|---------------------------|---------------------------|

|* * Working principle * * | Volumetric (constant volume conveying) | Kinetic energy (centrifugal pressure boosting) | Volumetric (internal compression)|

|* * Pressure range * * | Medium low pressure (≤ 0.8Bar) | Low pressure (≤ 0.3Bar) | Medium high pressure (0.8~1.5Bar)|

|* * Flow regulation * * | Only capable of variable frequency speed regulation | Adjustable air door/variable frequency | Variable frequency+internal compression ratio adjustment|

|* * Efficiency * * | Low (50-70) | High (70-85) | High (75-90)|

|* * Pulsation * * | Large airflow pulsation (requires muffler) | Stable airflow | Relatively stable|

---

**5、 Typical application scenarios**

1. * * Sewage treatment * *: aeration and oxygenation (requiring anti-corrosion design)

2. * * Pneumatic Conveying * *: Conveying granular materials such as grain and cement

3. * * Vacuum System * *: Used in combination with a vacuum pump

4. * * Chemical industry * *: Flammable gas transportation (explosion-proof required)

---

**6、 Frequently Asked Questions and Answers**

**Q1: Why is the noise of Roots blower loud? **

-Reason: Airflow pulsation+mechanical meshing vibration.

-Solution: Install a muffler and use a soundproof cover.

**Q2: How to adjust the air volume of Roots blower? **

-* * Effective method * *: Variable frequency speed regulation (Do not use valves for throttling, as it may cause damage due to overpressure).

**Q3: How does rotor clearance affect performance? **

-Excessive gap: Increased leakage and decreased efficiency.

-* * Gap too small * *: Friction generates heat and may cause jamming.

---

**Summary**

Roots blower achieves gas transportation through the change of rotor engagement volume, which has the advantages of simple structure, stable flow rate, and dirt resistance. However, it has low efficiency and high noise. When selecting, special attention should be paid to * * pressure requirements, medium characteristics, and sealing requirements * *.