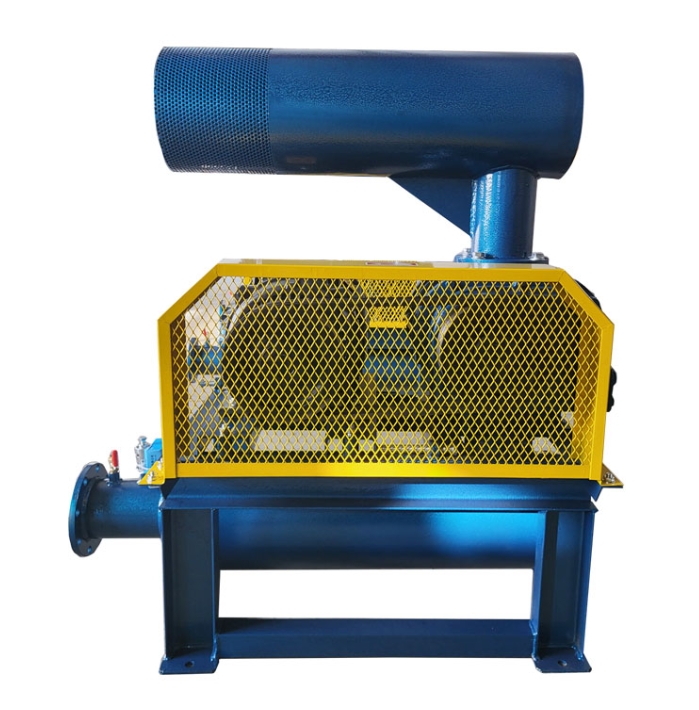

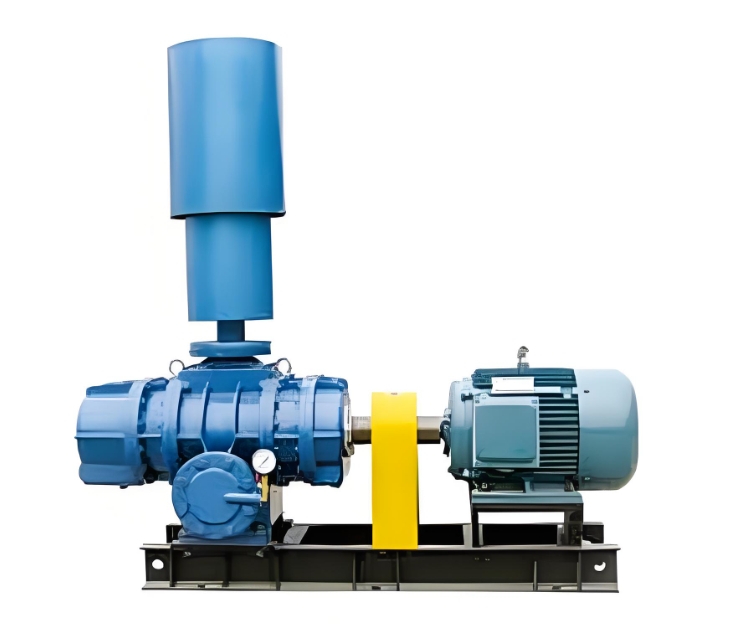

Practical guide for adjusting the clearance of Roots blower

As a commonly used equipment in the industrial field, gap adjustment is a key step in maintenance and upkeep of Roots blowers. Many operators often encounter the following pain points in their actual work: not knowing when to adjust the gap, worrying about improper adjustment affecting equipment life, and not being familiar enough with the adjustment steps leading to low efficiency. Today we will discuss this topic in detail.

Why adjust the clearance of Roots blower?

After running for a period of time, the clearance between the impeller and the casing, as well as between the impellers, will increase due to wear and tear. Excessive gaps can lead to:

-The decrease in air volume affects production efficiency

-Increased energy consumption and rising operating costs

-Increased noise and deteriorating working environment

-Increased vibration and shortened equipment lifespan

Preparation work before adjustment

Before making any adjustments, please make the following preparations:

-Stop the machine and cut off the power supply to ensure

-Prepare measuring tools such as feeler gauges and micrometers

-Clean the inside of the fan to remove dust and oil stains

-Refer to the equipment manual to understand the standard clearance values

3 Specific steps for gap adjustment

Taking the common three blade Roots blower as an example:

1 * * Measure current clearance * *: Use a feeler gauge to measure the clearance between the impeller and the casing, as well as between impellers, and record the values of each part

2 * * Determine adjustment direction * *: Determine whether to increase or decrease the gap based on the measurement results. The standard gap is usually between 0.15-0.40mm

3 * * Adjust the bearing seat * *: Loosen the fixing bolts of the bearing seat and change the position of the impeller by adding or removing shims or adjusting bolts

4 * * Synchronous adjustment * *: Ensure that the adjustment amount of the two impellers is consistent to avoid deviation

5 * * Retest verification * *: After adjustment, re measure the gaps between each part to ensure uniformity

6 * * Trial operation * *: Low speed no-load operation, observe vibration and noise conditions

4 Precautions after adjustment

-The gap should be checked again within 24 hours after the first operation

-Record the data and operating parameters before and after adjustment

-Regularly (recommended every 3 months) check for changes in gaps

-If abnormal vibration or noise is detected, the machine should be stopped immediately for inspection

5 Frequently Asked Questions and Answers

Q: What should I do if the air volume is still insufficient after adjusting the gap?

A: It may be due to seal wear or pipeline leakage, which needs to be checked

Q: Did the vibration increase after adjustment?

A: It may be due to uneven adjustment that the impeller is unbalanced and needs to be recalibrated

Remember, gap adjustment is a delicate task that requires patience and attention to detail. If you are not confident enough in your skills, it is recommended to hire a professional to handle it. Correct gap adjustment can make your Roots blower run more and have a longer lifespan!