The following is the core structure decomposition diagram and key component description of the two blade Roots fan, which helps you intuitively understand its internal structure:

---

**Structural diagram of two blade Roots fan (schematic diagram)**

```plaintext

____________________

|Export flange|

|____________________|

↑

_______________|_______________

| |

_________|_________ _________|_________

|Active rotor (two blades) | | Passive rotor (two blades)|

|(Rotation direction →) | | (Rotation direction ←)|

|___________________| |___________________|

| |

_________|_________ _________|_________

|Gearbox | | Bearing seat|

|(Main/secondary gear meshing) | | (Supporting rotor shaft)|

|__________________| |_________________|

| |

________|_____________ ________|_____________

|Motor | | Base|

|(Direct or belt drive) | | (including shock absorbers)|

|_____________________| |_____________________|

↑

____________________

|Entrance flange|

|____________________|

```

---

**Functional Description of Key Components**

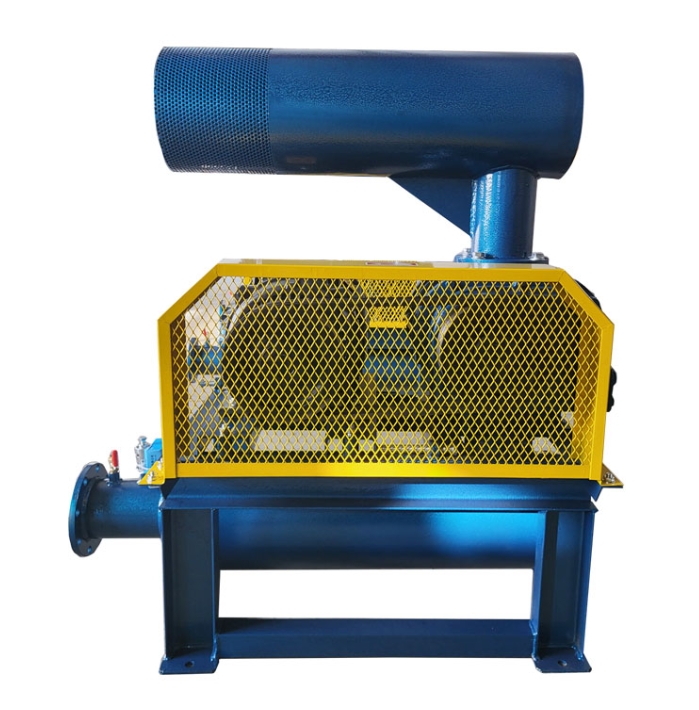

1. * * Rotor (core component)**

-Quantity: 2 two bladed rotors (active and passive).

-* * Shape * *: Straight blade, in the shape of an "∞" or gradually opening line.

-Phase difference: When installing two rotors, they should be staggered by 90 degrees to ensure sealing.

2. * * Gearbox**

-Function: Synchronize the rotation of two rotors (the active rotor drives the passive rotor through gears).

-Gear type: spur gear or helical gear (requires regular lubrication).

3. * * Bearing seat**

-Supporting rotor shaft: Typically, self-aligning roller bearings (resistant to radial loads) are used.

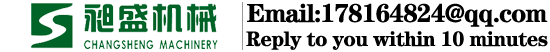

4. * * Shell**

-Material: Cast iron (HT250) or welded steel plate.

-Air chamber: wraps around the rotor to form a closed cavity, and the inlet and outlet directions can be customized.

5. * * Sealing system**

-Shaft seal: skeleton oil seal or mechanical seal (to prevent lubricating oil leakage).

-Gap sealing: The gap between the rotor and the housing is 0.15~0.25mm (affecting efficiency).

6. * * Drive mode**

-Direct connection type: The motor is directly connected to the drive shaft through a coupling.

-Belt type: speed regulation through pulley (tension needs to be adjusted regularly).

---

**Structural differences between two leaves and three leaves**

|* * Components * * | * * Two blade Roots blower * * | * * Three blade Roots blower * *|

|----------------|----------------------------------|----------------------------------|

|* * Rotor shape * * | Two straight blades | Three spiral twisted blades|

|* * Noise * * | Significant high-frequency pulsation (75-95dB) | Smoother airflow (70-85dB)|

|* * Efficiency * * | Low (Volumetric Efficiency 70-85) | High (Volumetric Efficiency 80-90)|

---

**Explosion diagram (decomposition of key components)**

If detailed engineering drawings (including dimension annotations) are required, it is recommended to:

1. Contact the manufacturer, such as Shandong, to provide CAD drawings.

2. * * Reference standard * *: JB/T 8941.1-2014 "Technical Conditions for General Purpose Roots Blowers".

---

**Maintenance Tips**

-* * Regular inspection * *: rotor clearance, gear oil condition, belt tightness (if applicable).

-* * Strictly prohibited from reversing * *: Reversing a two blade fan will instantly damage the blades!

If you need a specific model's structural diagram, please provide the fan brand or parameters (such as L22WD, GRB-50, etc.).